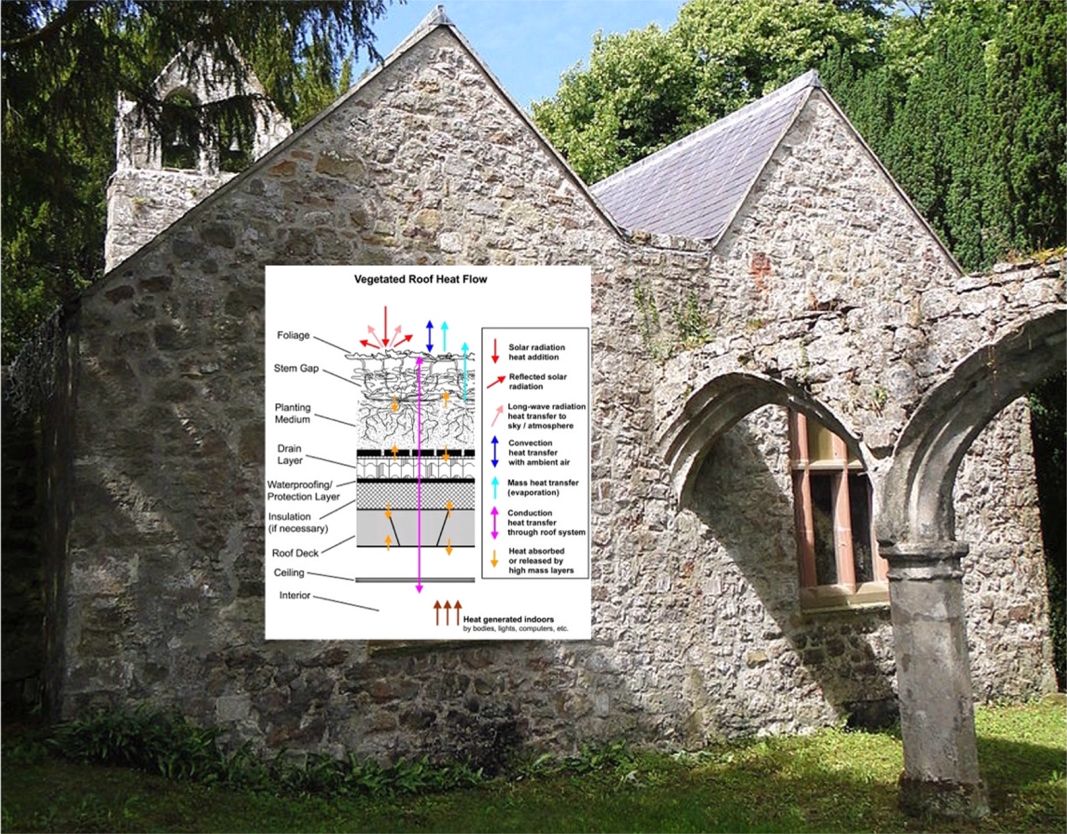

“Cooler than Cool Roofs: How Heat Doesn’t Move Through a Green Roof”

“Cooler than Cool Roofs: How Heat Doesn’t Move Through a Green Roof” is the 7-part Green Roof Energy Series explaining the key aspects of green roof heat transfer issues and the best ways to take advantage of a green roof’s energy benefits by Greenroofs.com collaborator Chris Wark.

Green Roof Energy Series Part 4: When Weight is Good

By Chris Wark, Energy Editor – Originally posted September 21, 2010

The weight of a green roof can sometimes present a structural challenge, but for controlling the flow of heat energy, that weight is a big benefit. If it is heavy enough, a roof system can take advantage of a material property called “thermal capacitance” to absorb heat during the day and then release it at night.

For some applications, like building design, this property is also known as “thermal mass” because it is related to weight and specifically refers to the amount of heat per pound that can be absorbed or released.

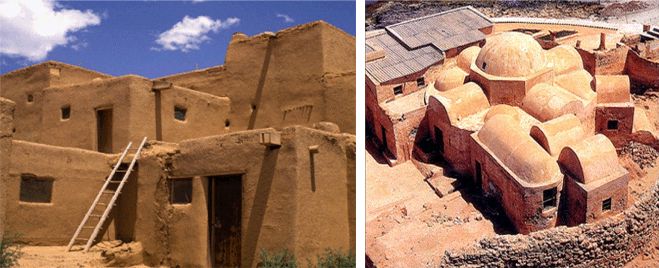

Left: Taos adobe village; Right: North African villa

Classic examples of where thermal mass is an advantage in buildings include adobe houses in the Southwest U.S., masonry buildings in the Middle East, and heavy stone structures in northern latitudes, all of which temporarily store the day’s heat in their heavy walls.

St Nidan’s Church, Llanidan, Anglesey, Wales stone church by Bencherlite – Own work, CC BY-SA 3.0, Wikipedia

But thermal mass is not just for buildings. It is universal, which means every object in the universe absorbs heat when its surroundings are hotter and releases that heat when the same surroundings cool down. A brick oven also takes advantage of thermal mass by collecting the flame’s heat into its dense brick and transferring that heat back out to food placed in the oven.

Speaking of food, remember that mention of hot potatoes in Part 1 of this series? Potatoes can take longer to cook and then hold their heat longer than many other foods because the fiber in potatoes has high thermal capacitance and they hold a lot of water, and also because potatoes are sort of round*. The “hold a lot of water” part is no coincidence – water has the highest thermal capacitance of any common substance on earth.

Left: San Gennaro Wood Fired Brick Oven Pizza & Ristorante and Right: The Seasoned Mom (Hungry yet?)

Water also provides an excellent analogy for thinking about how thermal mass works since mathematically, water and heat flow in much the same way. Think of a green roof as a heat sponge – just as a green roof can soak up rain water and then drain or evaporate that water slowly, it does pretty much the same thing with heat.

Let’s take our sponge analogy one step deeper into a little thought experiment. Think of a dry sponge sitting on a dry wooden cutting board in a sink. Now drip water on the sponge for several minutes. Depending on the absorptivity (now there’s a word for paper towel ads!) and thickness of the sponge, water may have started to soak all the way through, making the wood wet, but not by much because so much of the water gets stored in the sponge. After the dripping stops, eventually the sponge will dry out with some more of the water soaking into the wood and the rest evaporating. In the same way, a green roof will absorb heat from outside and then slowly release that heat back outside (and possibly inside) when it cools off, usually at night.

Thermal mass is just one way of controlling energy in a green roof. Copyright 2010 Christopher Wark

Again, thermal mass is associated with weight, not size. A 3-inch deep green roof with heavy planting medium and pulpy sedum may have more thermal mass than a 6-inch deep system with light-weight medium and wildflowers.

So, if an engineer were to calculate if a green roof could collect an entire day’s heat, they would need to know its weight per square foot, regardless of thickness.

Weight of deck, medium, and plants determine nearly all of the total thermal mass. Image: LiveRoof® cross-section

Speaking of engineers, this is where we start getting into the calculable aspects of moving energy through a green roof. If an engineer knows what he or she is doing, that engineer can include the roof insulation (if any) with the rest of the materials’ thermal capacitance in their equations to come up with a number known as a “time constant” which describes how fast a roof system can absorb heat.

For example, if it takes 12 hours to go from the coolest to the warmest outside temperature within a day, then the engineer should design the entire vegetated roof system to have a time constant of about 6 hours, depending on location. If done right, the center of the roof system will remain very close to the seasonal average ambient temperature with all diurnal (day and night) temperature swings eliminated.

To illustrate, the graph below shows results from an energy model of a green roof in Northern California. The green roof (green line) helps hold the roof temperature very close to the temperature inside the building (purple line), while the dark, exposed roof (black line) swings from cool at night to way too hot during mid-day. The time constant for this roof system was about 5 hours.

Copyright 2010 Christopher Wark

It seems that I have finally used the word “insulation” in our discussion of energy and controlling heat. Check back in next month when I use it a lot more.

*The reason why a potato’s shape affects the way it holds heat is very important, however, it is beyond the scope of this article, but not beyond the scope of a good introductory heat transfer textbook.

It seems that I have finally used the word “insulation” in our discussion of energy and controlling heat. Check back in next month when I use it a lot more.

*The reason why a potato’s shape affects the way it holds heat is very important, however, it is beyond the scope of this article, but not beyond the scope of a good introductory heat transfer textbook.

Copyright 2010 Christopher Wark

~ Chris Wark

References:

1. Incropera, Frank and DeWitt, David. Introduction to Heat Transfer. John Wiley and Sons, 1990. Classic heat transfer text with all the theory, equations and proper procedures an engineer needs to calculate thermal mass correctly.

2. Mills, A.F. Basic Heat and Mass Transfer. Irwin, 1995. Ditto.

3. www.ornl.gov/sci/roofs+walls/research/detailed_papers/thermal/index.html This is a pretty good study of thermal mass for one type of house construction. It compares energy savings for different weight wall systems in several different climates.

4. www.buildinggreen.com/auth/article.cfm/1998/4/1/Thermal-Mass-and-R-value-Making-Sense-of-a-Confusing-Issue/ Excellent discussion on how to use the word “insulation” when talking about thermal mass, including the pretend R-values that are used to describe massive construction elements.

5. www.concretethinker.com/solutions/Thermal-Mass.aspx Naturally, folks in the concrete business are more than happy to talk about thermal mass. This page has a nice concise explanation.

Publisher’s Note:

See Chris Wark’s entire 7-part Green Roof Energy Series from 2010-2011 online and in PDF: “Cooler Than Cool Roofs: How Heat Doesn’t Move Through a Green Roof.“

Christopher G. Wark

Christopher Wark is Principal of Wark Energy Consulting and the founder of Ponix MicroAg LLC, a development-stage company that is creating a line of compact plant enclosures for the CEA market. Chris has over 30 years of multidisciplinary engineering experience providing mechanical, analytical, and electronics support and services to manufacturers, universities and national labs. He holds Bachelor and Master of Science degrees in Mechanical Engineering (with a minor in Materials Science) from Washington State University where his graduate work focused on thermodynamics, fluid dynamics, and combustion.

For the past 19 years, Chris has focused his efforts on the development and promotion of technical solutions in architecture and construction. He has provided energy and environmental quality analysis, CFD modeling, and LEED consulting services for several engineering and building consulting firms in New York and California. In 2002, Chris established SHADE Consulting/Green Roof Innovations (GRI) with his wife Wendy.

With GRI, Chris developed several innovative modular eco-roof systems and in 2010, Chris designed a modular planting system in partnership with Guiyang Chuangjia High-Tech Accelerator Co. LTD in Guiyang, China. In Guiyang, he saw how most of the apartment balconies and rooftops were filled with vegetable gardens. The idea of providing an improved environment for food production in built environments, along with key GRI design concepts, inspired the development of the patented pPod™ miniature greenhouse developed by Ponix MicroAg.

Contact Christopher Wark at: cwark@pponix.com, 917-565-6919.

Greenroofs.comConnecting the Planet + Living Architecture

Greenroofs.comConnecting the Planet + Living Architecture