Additional Resources

The Hotchkiss School is located at 11 Interlaken Road Lakeville, CT 06039; 860.435.2591; visit their website and specifically their Environmental Initiatives and Green Buildings pages. Watch the 2:21 Hotchkiss School Biomass Treatment Facility – Project of the Week 6/13/16 video from Greenroofs.com on the greenroofsTV channel on YouTube. Greenroofs.com Project of the Week video photo credits: All courtesy of © David Sunberg-ESTO, Centerbrook Architects, Apex Green Roofs, Hotchkiss School, and ZinCo USA except for Adrien Delessert – Originally uploaded to Wikipedia by Adelesse, CC BY-SA 2.5, https://commons.wikimedia.org/w/index.php?curid=2852860, from Wikimedia Commons.

See the project profiles from Centerbrook Architects; ZinCo USA; O&G; and Apex Green Roofs. View beautiful photos of the Hotchkiss School Biomass Treatment Facility from ESTO. Read the October 25, 2013 Connecticut’s Greenest Building is Powerful by David K. Leff; May 1, 2013 Of biomass and green roofs: US school slashes winter energy bill by James Holloway in gizmag and the November/December 2013 PLANT POWER: The Hotchkiss School by Centerbrook Architects and Planners by Benjamin van Loon in gb&d. The Hotchkiss School Biomass Treatment Facility was featured in the month of September in the 2013 Greenroofs & Walls of the World(TM) Calendar.

Learn about the following companies in The Greenroof & Greenwall Directory: ZinCo USA, Inc.; Sika Sarnafil; and Apex Green Roofs.

The Hotchkiss School is located in one of the more beautiful geographic locations in the U.S. Northeast, and strives to develop in students a lifelong love of learning, responsible citizenship, and personal integrity. As described on the Hotchkiss school’s website, “The Hotchkiss School is an independent boarding school located in Lakeville, Connecticut. Founded in 1891, the school provides an education of unsurpassed quality to 600 students in grades 9 through 12, and to a small number of postgraduates. Students at Hotchkiss come from across the United States and 34 foreign countries. Graduates attend many of the most selective universities and colleges,” (Hotchkiss website).

In 2012 Hotchkiss built a state-of-the-art biomass central heating facility to replace an aging steam plant. Located between a golf course and marshes, the new LEED Gold certified Hotchkiss School’s Biomass Treatment Center provides heating for the entire preparatory school which includes 85 buildings encompassing 1.2 million square feet and about 600 residents. Sited at the bottom of a sloping landscape, the treatment center burns woodchips and reduces greenhouse gas emissions by a third to a half compared to the oil-fired boiler it replaced. Two Messersmith biomass boiler units, which operate at 80 to 82 percent efficiency, can generate 14 million BTUs per hour burning waste wood acquired from sustainably harvested, local forests that are certified by the Forest Stewardship Council.

The woodchips are replacing approximately 150,000 gallons of fuel oil per year and cut emissions overall, most dramatically sulfur dioxide by more than 90 percent. Waste ash from combustion is collected for use as fertilizer, and an electrostatic precipitator removes 95 percent of particulate matter from emissions (O&G).

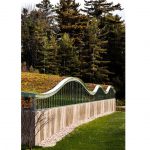

Installed in July, 2012, the green roof on the central heating facility/biomass plant is an exciting addition to an already beautiful campus, and its distinctive wavy living roof captures 50% of the site’s rainwater while simultaneously blending into the landscape (gb&d, 2013).

The building was an immediate icon in sustainable commercial construction. Centerbrook Architects, the architect of record for the entire building, succinctly explains the building and its importance as a green initiative for the Hotchkiss campus:

“The facility is part of Hotchkiss’ commitment to becoming a carbon-neutral campus by 2020. In order to merge with the surrounding landscape, the new building will have a low profile and an undulating, sloped green roof. The facility will be one of only three LEED certified power plants in the country,” (Hotchkiss website). Read more about the school’s Green Energy Initiatives.

This “US school has cut a six-figure sum from its winter energy bill by replacing its oil-burning boiler with woodchip biomass ones. The switch has reduced the school’s carbon footprint by between 35 and 45 percent. The boilers are housed in a brand new green-roofed building which has become only the third LEED-certified power facility in the US… As one should expect from a green roof, this one serves more than aesthetic purposes. Bioswales, specially designed sloping channels, combine with rain gardens to slow and filter rainwater before it enters the ground,” (gizmag, 2013).

Due to the use of precultivated sedum mats, laid directly onto the green roof substrate, the roof was covered by vegetation quickly. The sedum carpet green roof system was provided by ZinCo USA on top of a Sika Sarnafil waterproofing membrane. The roofing contractor, Greenwood Industries of Millbury, MA, performed the installation of the waterproofing membrane and sub-contracted the installation of the ZinCo USA green roof system to Apex Green Roofs of Somerville, MA.

The ZinCo USA Sedum Carpet green roof system is a built-in place system that contains 5 critical components for proper functionality on the Hotchkiss Biomass Facility’s serpentine roof top:

A protection mat is placed on top of the waterproofing membrane to protect the roof during installation and to retain water for the roof in times of extended drought. The Floradrain FD25-E drainage element – the proverbial “heart” of the green roof system – lies on top of the protection mat, hugging the waves of the roof (2/12 slope), ensuring proper drainage while retaining a specific amount of water for the roof’s vegetation. The Filter Sheet SF separates the 2.5″ of Zincoblend extensive growing media from the three-dimensional water retention cups of the FD25-E drainage element and a pre-cultivated vegetation mat is placed on top of the growing media achieving near 100% vegetated coverage in a short amount of time.

The result is the fantastic green roof seen in the images that will protect and beautify the Hotchkiss Biomass Treatment Facility Building for decades to come. Awards include the 2014 Associated General Contractors (AGC) Build Connecticut Award for Mid-Size New Constructions and the 2013 Connecticut Green Building Council Alexion Award of Excellence.

Greenroofs.comConnecting the Planet + Living Architecture

Greenroofs.comConnecting the Planet + Living Architecture